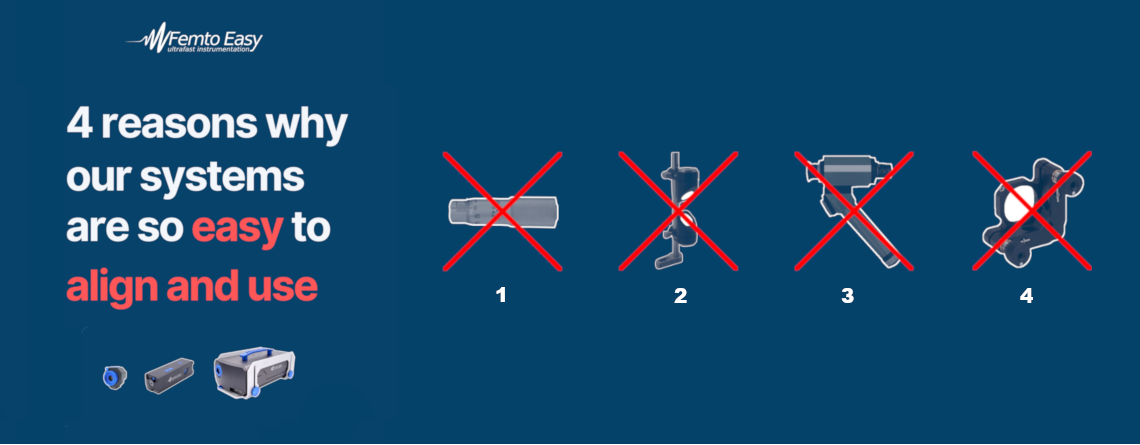

4 reasons why Femto Easy systems are so easy to align and use

Embarking on the journey of ultrafast laser characterization? Uncover the simplicity and effectiveness behind Femto Easy autocorrelators and FROG systems, as we delve into four compelling reasons why aligning and utilizing these tools for your ultrafast laser characterization is a breeze. Explore the seamless alignment process and discover how these cutting-edge technologies can elevate the precision of your measurements effortlessly.

1. No micrometer screw needed

Unlike certain comparable systems that demand the use of external micrometer screws for aligning the internal optical path to factory settings, Femto Easy autocorrelators and FROG systems eliminate this requirement. These devices arrive fully factory calibrated and aligned, sparing users the need to manually adjust screw positions or search for factory values in manuals. With Femto Easy technology, experience hassle-free operation—ready to measure straight out of the box, without the need for additional adjustments or calibrations.

2. No periscope needed

Laser beams often exit systems at varying heights from measurement devices, with fixed device heights compounding the challenge. Femto Easy systems offer a solution by enabling seamless adjustment of the device height to match the laser beam height. This adaptability is facilitated by the compact design of our devices, allowing easy mounting on basic optical posts for height adjustments. For larger systems like FROG, a purpose-built housing incorporates a unique adjustable height mount, ensuring a tailored and reliable alignment process.

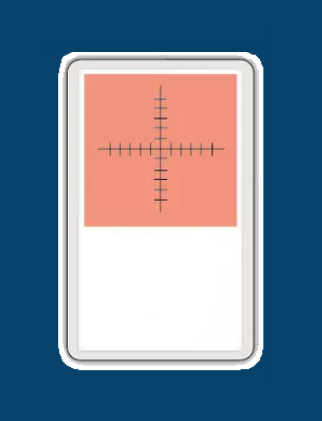

3. No IR viewer needed

Streamlining alignment procedures is crucial, and with Femto Easy devices, you can simplify the process. Unlike cumbersome methods that involve observing the internal beam through multiple reflections until it hits a transparent target on the housing, our technology eliminates the need for such complexities. When utilizing a widely-used IR laser, traditional processes mandate visualizing the beam on the target, typically done with an IR viewer. With Femto Easy devices, this requirement is bypassed, as a simple IR card is all that’s necessary to observe the beam upon entry into the system.

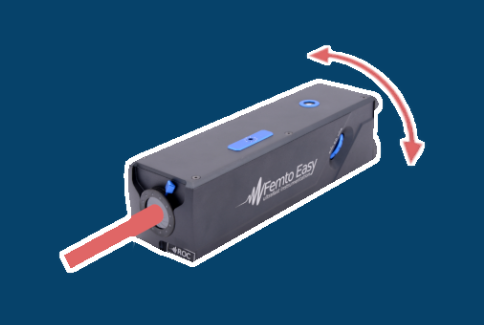

4. No steering mirror needed

Diverging from traditional autocorrelators and FROG systems, our innovative technology eliminates the necessity for a pair of steering mirrors to align the beam with the measurement device. Achieving alignment with our autocorrelators and FROG systems is a straightforward process—simply ensure the beam is centered into the input iris, followed by a slight rotation of the device’s back until the maximal signal is attained.

In conclusion, the ease of alignment and usage presented by Femto Easy systems stands as a testament to their commitment to simplifying the intricate process of ultrafast laser characterization. With four compelling reasons explored in this post, we’ve highlighted how these advanced technologies redefine convenience and precision in the field. Whether you’re a seasoned researcher or a newcomer to ultrafast laser characterization, the user-friendly design of Femto Easy autocorrelators and FROG systems opens up a world of possibilities. Say goodbye to cumbersome alignment procedures and welcome a new era of effortless and accurate measurements with Femto Easy, empowering you to push the boundaries of ultrafast laser research.